Automated.

Safe.

Reliable.

We offer an end-to-end solution from image acquisition to maintenance insights to optimise your aircraft inspection process.

Automated.

Safe.

Reliable.

We offer an end-to-end solution from image acquisition to maintenance insights to optimise your aircraft inspection process.

Donecle offers a full end-to-end solution which goes far beyond image acquisition.

We help you get your aircraft back in the air in 3 steps.

Discover how it works

Collect images automatically

Our drone automatically scans and collects high-resolution images of the inspected structure.

Turn data into actionable insights

Pictures are automatically sent and processed in our image analysis software:

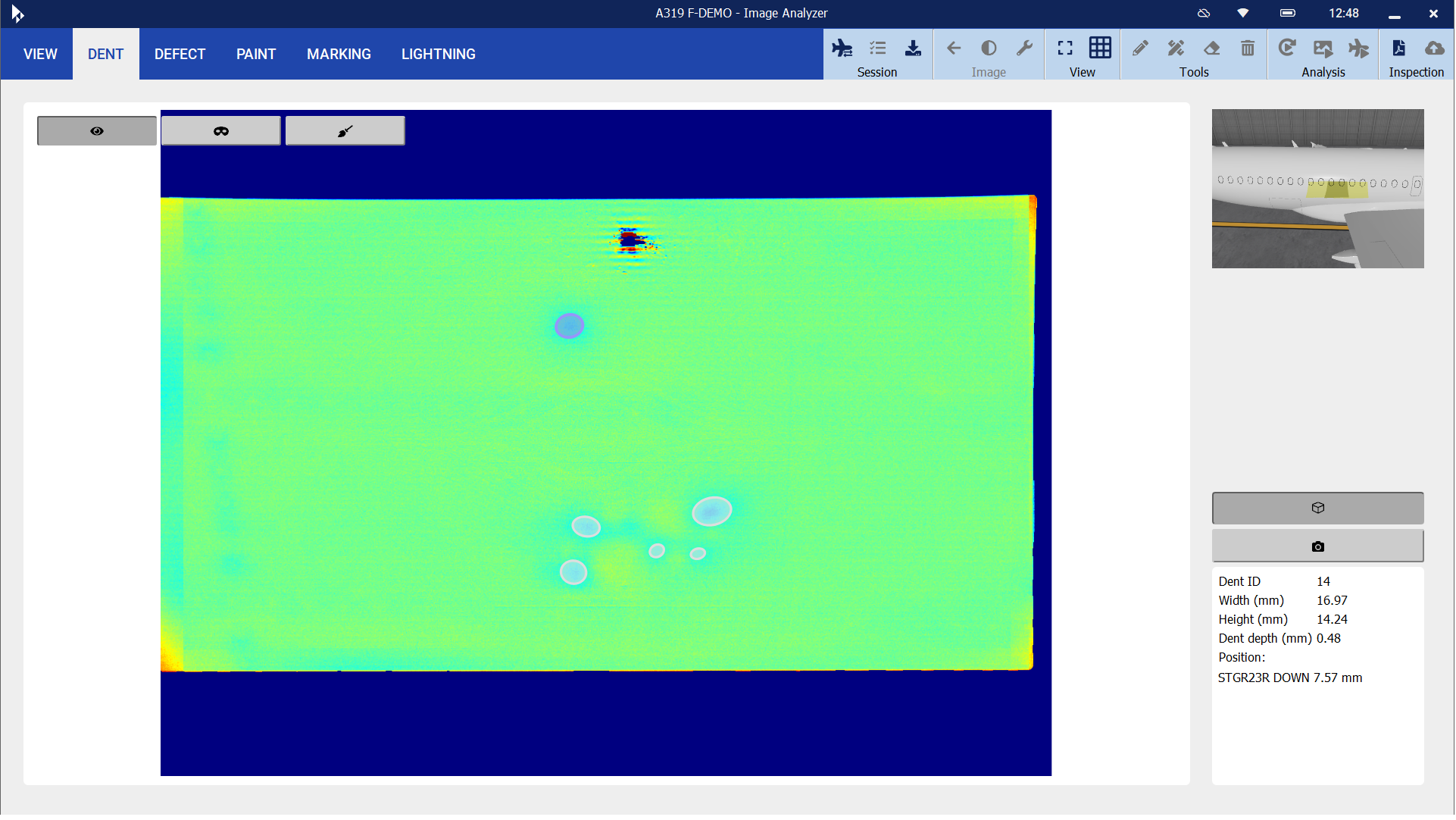

Images taken by the drone are displayed on a 3D model of the aircraft with easy navigation tools. Our software allows image visualization, zoom in/out and provides the exact location of the picture relative to aircraft structural elements. Specific tools provide automated analysis of defects, markings and paint quality.

Thanks to the 3D sensor onboard of our Iris 3D drone, we automatically detect and measure dents on aircraft surface, down 0.1mm depth accuracy.

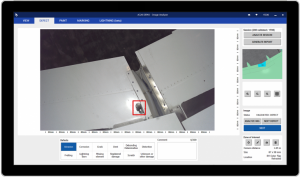

We assist the inspector in the general visual inspection process, giving tools to identify and categorize defects and damages on the aircraft surface. Our algorithms based on machine learning suggest defects to accelerate the time of this process, including lightning strike. A report is automatically produced to give a summary of observed defects and keep track.

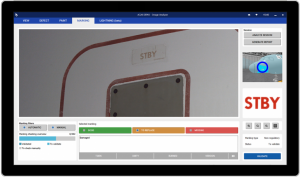

The software automatically analyses and compares each regulatory marking to the customer’s database and tags them as good, missing or to be replaced. A report is then automatically generated to give status of markings with direct retrieval of P/N number for easy and reliable reordering.

Our software provides an indication on the state of the aircraft’s livery and paint by automatically mapping rivet/screw rash and peeling on the aircraft skin. The final report assesses the global quality of paint wear to optimize painting programs and monitor paint aging evolution over time and across the fleet.

We automatically detect lightning strikes thanks to our computer vision algorithms and generate reports with precise location of impacts according to frame and stringers.

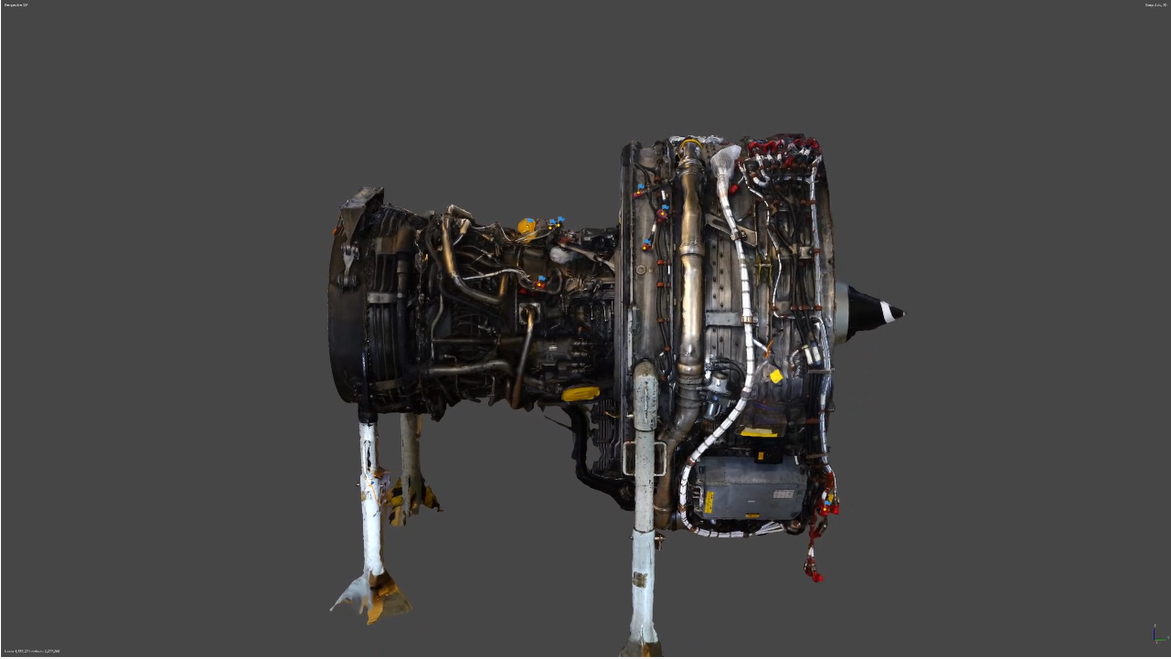

With Dronétix Technologie, we perform inspections of aircraft components. For parts such as landing gear or engines, the software allows you to visualise your part in 3D, virtually rotate around the part, zoom in/out and inspect. Finalise the report to get traceability on each inspections.

Build objective digital history

Inspection data and reports are systematically saved on Donecle’s secure cloud platform:

From the release of our first Drone end of 2018 to the new Iris family, our products are designed to meet high standards.

Our unique patented laser technology allows precise positioning (centimetric) and does not require GPS or external sensor.

Our fail-safe design guarantees the mission’s safety thanks to hardware redundancy and obstacle detection.

The camera gimbal is automatically piloted to follow every curvature to provide clear images all around.

Our drone enables detection of: defects down to 1mm² , dent down to 0.1mm, and ensures accurate frame/stringer positioning of damages.

We make your visual inspections faster, repeatable and more reliable. We allow you to quickly update your job cards to optimize maintenance process. We put your aircraft quicker back in the air and reduce AOG time and costs.

We help your resources focus on high-value tasks and make their job safer and easier. We reduce risks of errors due to human factors. We inspire young generations to join the industry thanks to new technologies.

We provide objective, reliable data and actionable information in a timely manner. We leave no room to misinterpretation and bring a protection against warranty claims. We build a digital history of past inspections for trend monitoring.

Copyright Dassault Aviation Cyrille Cosmao

We contribute to the modernization of your tools and methods, providing a unique patented technology. We help you to move towards a paperless workflow and support the digitalization of your maintenance process.

Access our brochure:

Download

Discover direct applications of Donecle for your daily tasks:

Use cases

Discover who we are working with:

Our customers

Find answers to most frequent asked questions in the FAQ