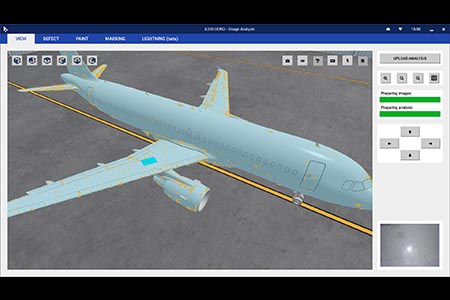

Donecle is an aircraft inspection solution. Our drone Iris combining 100% automated drone to an image analysis software. The solution helps optimizing maintenance activities, reducing the inspection time to less than 1 hour, supporting analysis of damages on the aircraft structure, automatically generating reports, and improving traceability over time.

Ressources

Ressources

Frequently Asked Questions (FAQ)

Who should use Iris solution?

Airlines and MROs seeking more efficient inspections during line and base maintenance; aircraft manufacturers willing to ensure highest level of quality before delivery; military aircraft operators who look for solutions for in-service support (MRO) and build aircraft digital history.

Does it require GPS signal?

No. As we are aware that GPS is often not available in hangars, we have developed a laser positioning technology which does not require any GPS signal or any other sensor.

Is it operational?

Yes. Donecle’s solution is already deployed and running in several airlines and MROs worldwide. This is not just a concept: aircraft are being inspected by Donecle’s solution every day.

What are the typical use cases?

Main applications cover: general visual inspections, lightning strike, marking checks, paint wear evaluation, pre-delivery quality check, traceability.

Is it approved by authorities?

Donecle is listed in Airbus A320 AMM, and is collaborating with OEMs and regulatory authorities to qualify our solution as an approved alternative inspection method and is already engaged in validation programmes. Not all inspections are subject to regulations (eg. paint quality checks, inspection of mandatory decals).

How does it work?

The solution works in 3 steps. The first step is to collect pictures of the entire skin of the aircraft thanks to the drone. The drone does not require a pilot as it is automated and uses a unique laser technology to position itself. The second step is to process and analyse the images thanks to Donecle’s software which automatically generates reports on defects, paint quality and markings. The third step is to store the data and reports on the cloud platform to be able to build a digital history of the aircraft and keep track of past inspections.

Why is it innovative?

Donecle’s drone is 100% automated (no pilot) and does not require any GPS or beacon as it uses a patented laser positioning technology. Flight missions are pre-planned and embedded in the drone. The drone has been specifically designed to fly around aircraft.

The solution offered by Donecle is a full end-to-end package including the drone, the image analysis software, the secured data history hosting, the training and maintenance.

It enables operators and MROs to acquire a complete “snapshot” of the aircraft at a specific moment in time. There is currently no other means of acquiring a full set of structured data on the aircraft structure, contrary to what is done on other elements of the aircraft (engines, components, etc.).

Which part of the aircraft structure is inspected by the drone?

We acquire images of the complete aircraft external surface, including upper and lower parts, wings (top and bottom parts), tailplane, radome. We cover 100% of upper areas that are difficult to access. On some aircraft types, a limited number of lower areas (eg. around landing gears) may be “unfliable”.

Which type of aircraft are you able to inspect?

All aircraft from A320 and B737 families and any smaller civil aircraft (turboprop, regional jets, business jets…). We are currently working to extend the capabilities on widebodies.

We can also address military aircraft in the fighter range as well as transportation carriers.

We are welcoming all new requests for new aircraft type whether they are civil, military or business jets.

Where is the data stored?

Inspection data is stored on Donecle’s cloud. Individual airline or MRO customer data is segregated and cannot be accessed by third parties unless explicitly requested by our Donecle’s customer. Data is redundantly stored to avoid potential loss and subject to frequent backups.

Is it safe?

Yes. We design, develop and assemble our own drone platform in-house specifically for aircraft inspections. It allows us to take into account stringent safety requirements associated with flying in a demanding environment, around a multimillion dollar aircraft. In particular, our systems comprise hardware redundancy features, software fail-safe and obstacle detection capabilities.