Improve the efficiency of your aircraft inspections

Improve the efficiency of your aircraft inspections

Use Cases

Aircraft are inspected visually on a regular basis to ensure their airworthiness. Scheduled and unscheduled visual inspections are always a long, costly process.

Explore our different use cases and learn how you can benefit from Donecle’s technology to optimize your maintenance process.

Whether you are an Airline, a MRO, a Lessor or an aircraft manufacturer, we have the solution to inspect your aircraft faster and more efficiently.

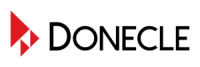

Lightning Strike

Reduce turnaround time and AOG costs after a lightning strike

- Challenge

When an aircraft is struck by lightning, it has to be grounded for inspection until the entry/exit points are found.

This takes several hours and leads to operational losses for operators.

- Our solution

Complete automated inspection and detection of lightning strike impacts with Donecle drone and image analysis software in less than 2h ensuring rapid aircraft availability.

Learn more

<2 hours

instead of 6 to 12 hours for manual inspections

Get your aircraft back in the air,

where it belongs

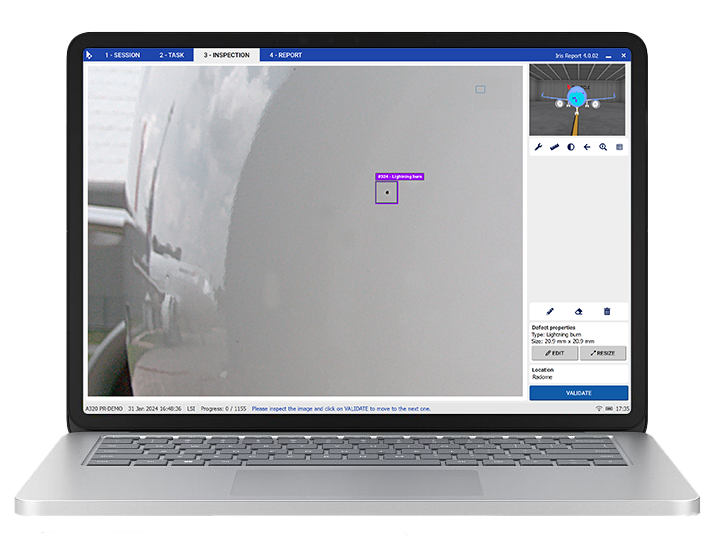

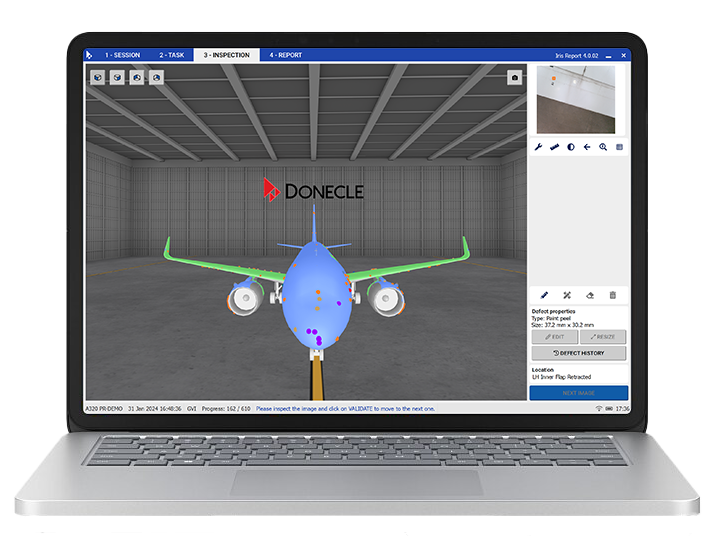

General Visual Inspection

Speed up and increase reliability of aircraft visual inspections

- Challenge

Zonal inspections (GVI) are a long, costly and subjective process. Accurate detection and location of damages is challenging for inspectors.

Inefficiencies lead to lengthy email exchanges with OEMs, last-minute job card updates causing late deliveries or warranty claims from operators and lessors.

- Our solution

Automated drone inspection when aircraft enters the hangar delivers a detailed and objective inspection report.

Precise positioning of all defects vs frames & stringers enables reliable damage mapping and objective comparison of aircraft status over time.

No defect

positionning mistake

Improved

safety

Save time

and costs

Digital aircraft history

and paperless process

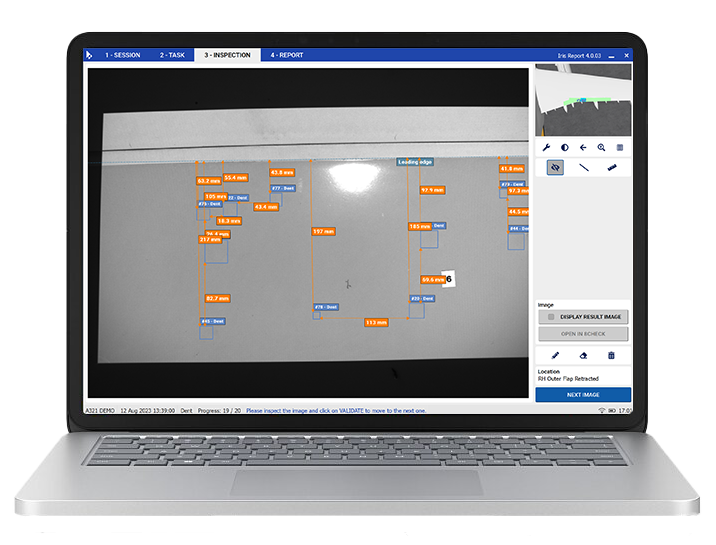

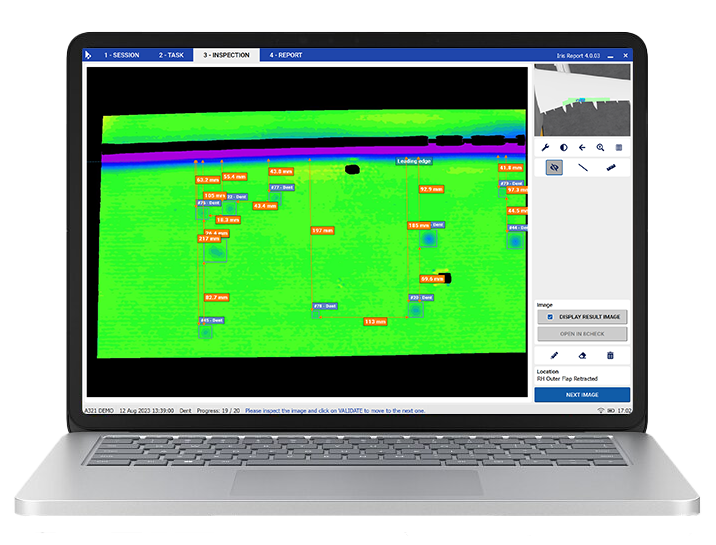

Dent

Quick detection and dent measurement

- Challenge

Detecting and measuring the dents and buckles on an aircraft’s surface is time-consuming. Detection is performed by hand, and the measurements are unreliable and depend on the various techniques applied.

- Our solution

Donecle has developed, a solution to detect and measure dents and buckles 50 times faster than the manual method.

Our fully automated Iris 3D drone is equipped with the 8tree’s dent CHECK technology to improve traceability and reliability.

Precise detection

and measurement

50 times faster

than current method

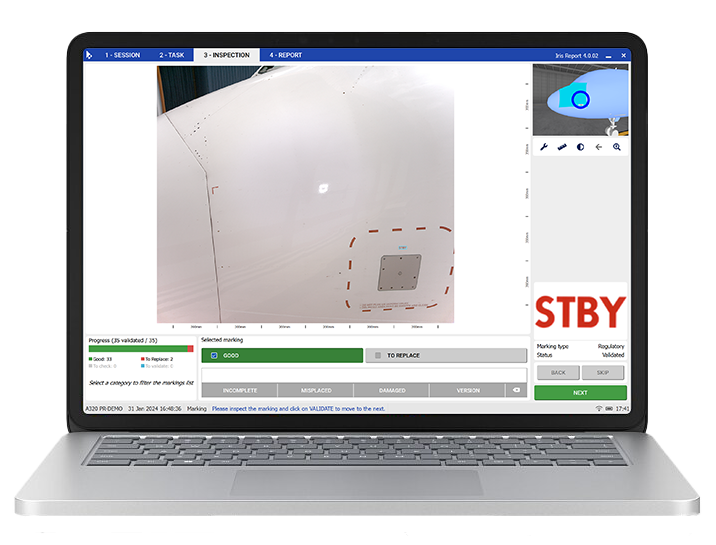

Markings Check

Increase efficiency of marking and placard checks

- Challenge

Checking 150 to 300 placards on a narrowbody aircraft takes several hours. Nevertheless, missing or invalid placards can lead to fines or aircraft grounding when detected during ramp inspections.

- Our solution

Donecle makes placard checks faster and objective with automated inspection of all markings and placards in less than 1 hour.

We help you identify missing P/Ns for reordering while ensuring compliance with ramp audits.

Learn more

Reduce

AOG risk

Eliminate indirect costs

and inspection burden

Traceability

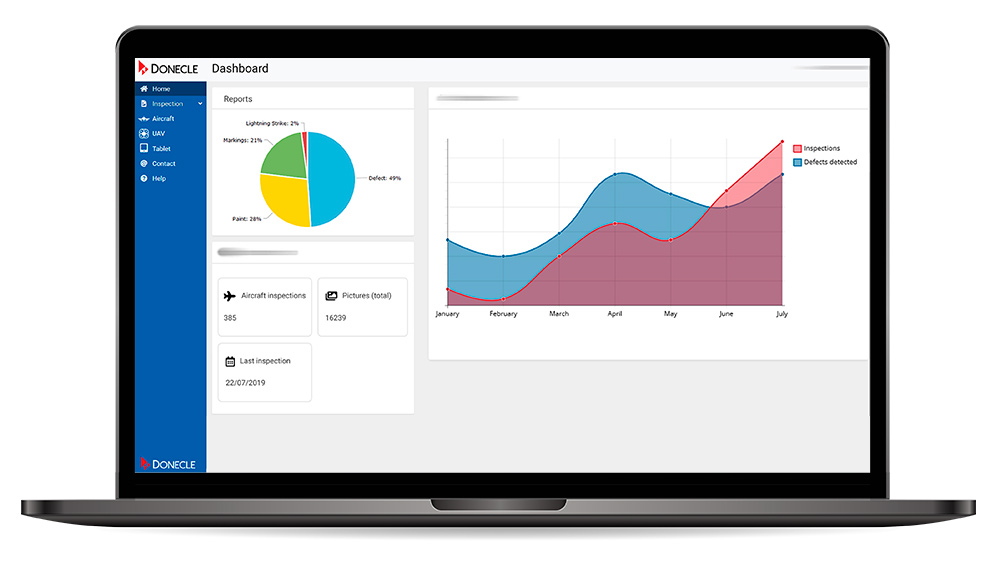

Keep reliable and objective track of past visual inspections

- Challenge

Aircraft visual inspection is still a manual process with limited tracking of past damage reports.

Analysis can be incomplete or subjective: it is hard to determine how a damage has evolved from a previous check if it was misreported initially.

- Our solution

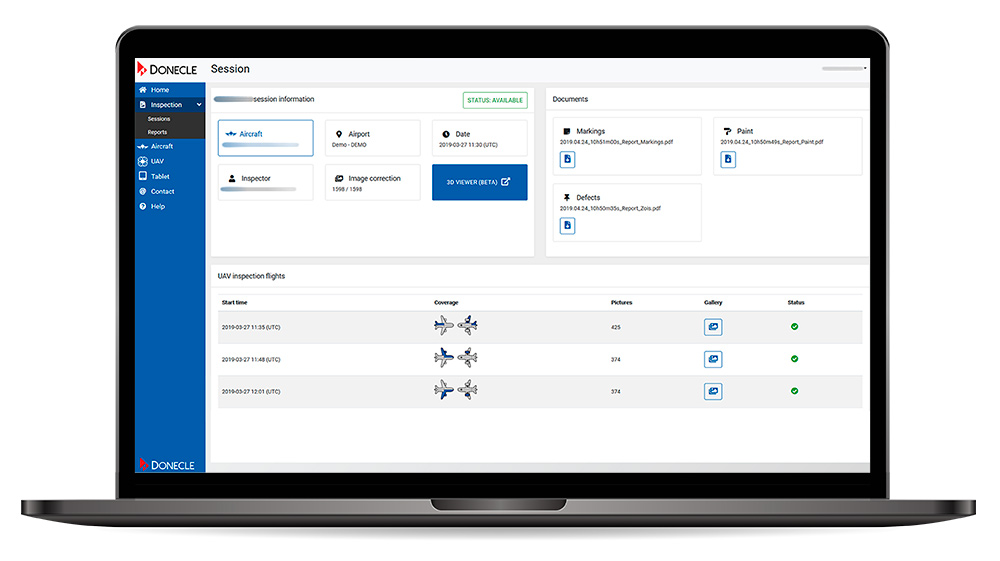

All data and reports from past inspections are stored on a secure cloud platform. It guarantees full traceability of aircraft status over time, building a digital history of each airplane and allowing comparison of defects from one inspection to another.

Aircraft

digital history

Paperless

process

Other use cases

Donecle’s unique technology can serve multiple other applications and lead to many additional benefits:

▸ End-of-lease checks: smoother interaction with lessors and operators

▸ Paint schedule optimization in collaboration with appearance department

▸ Military aircraft inspections

▸ Business jet inspections

▸ Quality inspection at final assembly line

▸ Etc.

You have a specific use case that you want to submit to us? Let’s work together!